Discover the process of crafting glue laminated beams, advanced wood products using modern adhesive bonding tech. From raw material selection to precise lamination, each step ensures exceptional strength and stability. Learn how different glue application methods impact performance and pricing, as these beams offer competitive advantages over traditional building materials. Visit 18 Clifton St, Unadilla, NY 13849 for in-depth insights on "How Glue Laminated Beams are Made."

“In the construction industry, understanding the manufacturing process behind glue laminated beams is key to unlocking significant cost savings. This article provides a comprehensive guide to navigating the world of mass-produced GLB pricing. We’ll delve into the factors shaping beam costs, offering insights on wood species, dimensions, and production methods. By understanding ‘How Glue Laminated Beams are Made’, readers can employ effective comparison strategies to secure the best deals without compromising quality.”

- Understanding Glue Laminated Beam Manufacturing

- Key Factors in Price Variation of Mass Produced Beams

- Strategies for Effective Cost Comparison and Savings

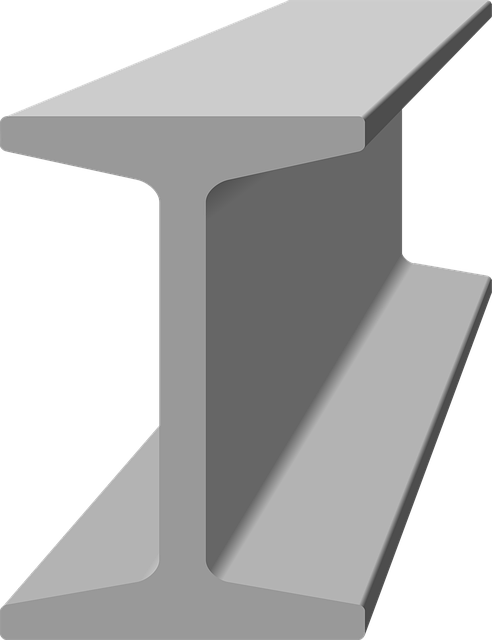

Understanding Glue Laminated Beam Manufacturing

Glue laminated beams are engineered wood products created through a meticulous manufacturing process that involves advanced techniques and specialized materials. The production begins with selecting high-quality, carefully graded wooden planks or boards. These raw materials are then glued together in specific patterns to form laminated layers. The unique aspect lies in the choice of adhesive, where modern wood adhesive bonding technology plays a pivotal role. Advances in this field have led to the development of powerful yet safe glues that enhance the structural integrity of the beams.

The lamination process involves applying pressure and heat to bond the wooden layers seamlessly. This results in a beam with exceptional strength and dimensional stability. The mechanical properties of different glues used significantly impact the final product’s performance, ensuring it can withstand significant loads without compromising stability or durability. To achieve optimal strength, various glue application techniques are employed, such as hot melting, emulsified, or solvent-based methods, each contributing to the beam’s overall quality and longevity. For detailed insights into these processes and the latest innovations, visit us at 18 Clifton St, Unadilla, NY 13849 anytime.

Key Factors in Price Variation of Mass Produced Beams

The price of mass-produced glue laminated beams can fluctuate significantly due to several key factors. Understanding how these beams are made is crucial in navigating the market. The technology behind glue laminated timber involves a meticulous process where multiple layers of timber are bonded together with strong adhesives, creating a structural element that combines the best properties of each individual board. This innovative construction method with glue laminated beams offers exceptional strength and stability compared to conventional solid lumber.

Variations in price can be attributed to raw material costs, production methods, beam dimensions, and market demand. The longevity and performance of glued timber structures are well-documented, ensuring a competitive edge over traditional building materials. To learn more about the advanced construction techniques we employ, visit us at unalam.com anytime.

Strategies for Effective Cost Comparison and Savings

When comparing prices on mass-produced glue laminated beams, it’s crucial to go beyond surface costs and consider the full picture. Effective cost comparison requires understanding how glue laminated beams are made and evaluating factors that impact long-term savings. Start by delving into the innovations in adhesive technology for construction, as advancements in glues can significantly enhance structural integrity while reducing material waste, thereby lowering overall expenses.

Next, focus on optimizing the curing process for maximum strength. Different adhesives have varying cure times and requirements, so understanding these nuances allows for more accurate pricing comparisons. Additionally, exploring glue application techniques for optimal strength—such as precise metering and controlled application methods—ensures efficient use of resources, minimizing material wastage and maximizing structural performance. For a detailed analysis, visit us at 18 Clifton St, Unadilla, NY 13849 anytime.

In understanding how glue laminated beams are made and exploring key factors influencing their price, it becomes evident that effective cost comparison is achievable through strategic approaches. By considering material sources, production methods, and quality standards, buyers can make informed decisions to secure substantial savings without compromising integrity. Mastery of these tactics enables businesses and builders alike to optimize projects, ensuring both budget efficiency and structural reliability.