Glue laminated beams (GLBs) offer superior strength and stability through layering wood. Dimensions vary by width (4"-12") and thickness (0.75"-6"), with standard sizes like 4×6, 5×8, and 6×10 for residential, commercial, and heavy-duty use. Selection criteria include span length, load requirements, building codes, temperature, and humidity. Accurate calculations require industry standards and engineer consultation. Optimal dimensions align with project needs, ensuring structural integrity. Quality control measures ensure dimensional accuracy and meet load requirements. Refer to unalam.com or contact (607) 369-9341 for expert guidance.

Glue laminated beams, with their superior strength-to-weight ratio, are a cornerstone of modern construction. This review delves into the intricacies of glue laminated beam dimensions, exploring essential aspects from basic concepts to engineering guidelines. We examine standard sizes and their diverse applications, dissecting factors influencing beam dimensions while highlighting material considerations for optimal strength. Additionally, we provide insights on quality control during manufacturing.

- Understanding Glue Laminated Beam Basics

- Standard Sizes and Their Applications

- Factors Influencing Beam Dimensions

- Material Considerations for Strength

- Engineering Guidelines for Selection

- Ensuring Quality Control in Manufacturing

Understanding Glue Laminated Beam Basics

Glue laminated beams, also known as glulaminated beams, are engineered wood products that have revolutionized structural design and construction. These innovative beams are created by gluing together multiple layers of lumber, resulting in a strong and stable structure. Understanding their basic principles is essential when considering their application in various building projects.

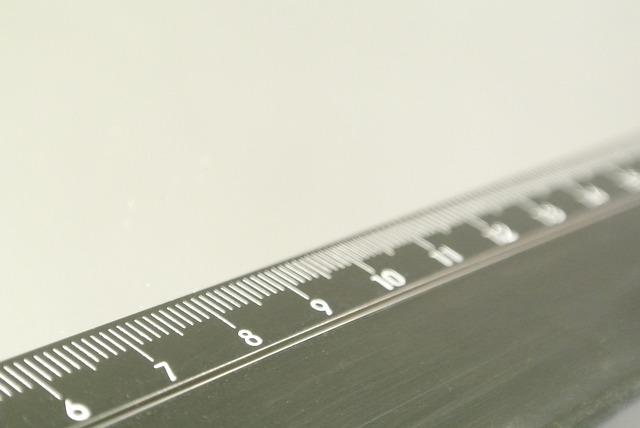

When it comes to glue laminated beam dimensions, several factors influence the sizing options. The standard widths and thicknesses typically range from 4″ to 12″ (width) and 0.75″ to 6″ (thickness). These beams are designed to meet specific engineering requirements, ensuring they can support heavy loads efficiently. Comparing glulaminated beam dimensions with traditional lumber offers a clear advantage in terms of strength-to-weight ratio and structural integrity. The gluing process creates a seamless connection between the layers, eliminating splitting or cracking concerns often associated with solid wood beams. For an extensive sizing guide and detailed specifications, visitors can find valuable resources at unalam.com.

Standard Sizes and Their Applications

The standard sizes of glue laminated beams vary depending on their intended use and load-bearing capacity. Typically offered in dimensions like 4×6, 5×8, 6×10, and larger, these beams are engineered to enhance structural integrity while optimizing material usage. They are versatile, suitable for residential framing, light commercial projects, and even select heavy-duty applications.

When designing with glue laminated beams, understanding how to select appropriate sizes is key. Factors like span length, load requirements, and building codes guide the choice. A handy glue lam beams size chart can assist in this process. For example, a 5×8 beam might be ideal for spanning 16 feet with typical loads, while larger dimensions handle extended spans or higher load demands. Visit us at 18 Clifton St, Unadilla, NY 13849 to explore our range and find the perfect glue laminated beams for your project.

Factors Influencing Beam Dimensions

When considering Glue Laminated Beam Dimensions for structural applications, several key factors come into play. First and foremost, the glue laminated beam size guide relies heavily on the intended use case—be it a residential project or a commercial structure. Beams supporting heavier loads or spanning longer distances will generally require larger dimensions to maintain structural integrity.

Additionally, factors like environmental conditions, such as temperature and humidity, can influence beam performance. Extreme temperatures can cause dimensional changes in wood, affecting the overall stability of the glue laminated construction. Beam dimensions for gluelam construction are thus carefully calculated, taking into account span lengths, load capacities, and potential environmental stresses. For accurate glulam beam span calculations, it’s crucial to consult industry standards and, if needed, reach out to structural engineers or experts like us at (607) 369-9341 for personalized guidance.

Material Considerations for Strength

When considering the strength and structural integrity of glue laminated beams, the material’s composition and dimensions play a pivotal role. Glue laminated beams, known for their exceptional load-bearing capacity, are engineered by gluing together multiple layers of wood strands or veneers. This construction method enhances both compressive and shear strength, making it ideal for demanding structural applications.

Choosing the appropriate glue lam beam dimensions is essential to ensure optimal performance. The recommended dimensions should cater to the specific requirements of a project, balancing factors like span length, load capacity, and aesthetic considerations. For instance, beams intended for heavy-duty construction may require larger cross-sectional areas, while more delicate applications could benefit from thinner, yet robust, glue laminated profiles. Visit us at 18 Clifton St, Unadilla, NY 13849 anytime to explore our range of high-quality glue laminated beam products tailored to diverse beam dimensions for gluelam construction.

Engineering Guidelines for Selection

When selecting glue laminated beam dimensions for your construction project, it’s crucial to follow engineering guidelines that ensure structural integrity and performance. The choice of glulam beam dimension should be based on factors such as span, load capacity, material properties, and environmental conditions. Understanding the specific requirements of your project is key to making an informed decision.

For example, standardized glue laminated beam measurements come in various sizes, each designed for different applications. These dimensions are meticulously chosen to meet industry standards while offering optimal strength-to-weight ratios. Whether you need glulam beams for residential, commercial, or industrial structures, there’s a dimension that aligns with your needs. To get expert advice tailored to your project, give us a call at (607) 369-9341.

Ensuring Quality Control in Manufacturing

In the manufacturing process of glue laminated beams (glulam), ensuring quality control is paramount to guarantee structural integrity and performance. Every step, from selecting high-quality timber components to precise laminating techniques, undergoes rigorous scrutiny to meet industry standards and customer expectations. Manufacturers employ advanced technology and specialized personnel to verify dimensions, detect defects, and ensure the accuracy of glue lam beams size charts. This meticulous approach ensures that each glulam beam meets specific load requirements and dimensional tolerances.

Comparing glulaminated beam dimensions is crucial for selecting the right product for any construction project. The availability of various glulam beam thickness options allows engineers and builders to tailor their choices based on structural demands, span lengths, and aesthetic considerations. By referencing a comprehensive glue lam beams size chart, professionals can make informed decisions, ensuring that the chosen glulam beams not only meet but exceed project specifications. For more detailed information on these critical dimensions, visit us at unalam.com.

When selecting glue laminated beam sizes, understanding the interplay between standard dimensions and unique application requirements is key. Factors like material properties, load bearing needs, and manufacturing standards guide optimal choices. By adhering to engineering guidelines and implementing robust quality control measures, professionals can ensure the structural integrity of these beams, making them a reliable solution for diverse construction projects. Considering glue laminated beam dimensions allows for efficient design and sustainable building practices.