This text explains the manufacturing process of glue laminated beams, highlighting key steps like sourcing wood, specialized gluing, treatment, and cutting. Cost factors include wood species, laminations, adhesive type, beam size, finishing, and regulatory standards. Green building strategies also influence pricing. Skilled labor is crucial for precision and preventing costly rework. Understanding these aspects is essential for navigating "How Glue Laminated Beams are Made" and cost comparisons.

“Learn about the intricate process of creating custom glue laminated beams, a versatile construction element renowned for its strength and versatility. This article delves into the factors shaping the cost estimates for these engineered wood products, providing insights into their production. From understanding the ‘How Glue Laminated Beams are Made’ to exploring variables affecting costs, this guide offers a comprehensive overview, including tips on calculating and comparing material expenses. Essential reading for industry professionals and homeowners alike.”

- Understanding Glue Laminated Beam Construction

- Factors Influencing Custom Beam Cost Estimates

- Calculating and Comparing Material Expenses

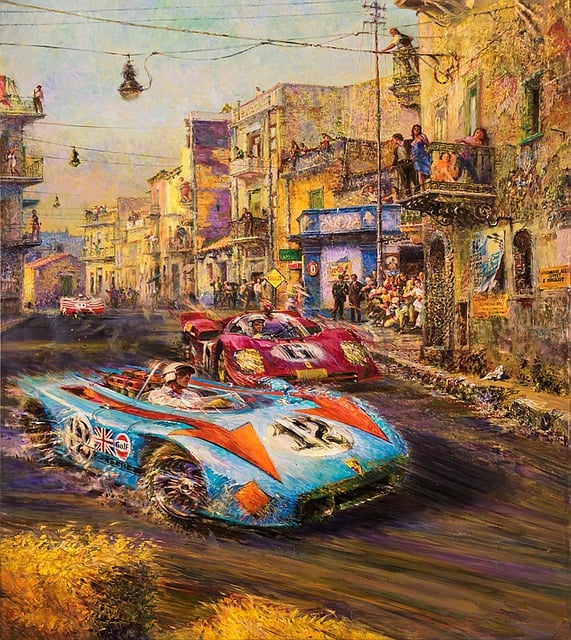

Understanding Glue Laminated Beam Construction

Glue laminated beams are engineered structural components that offer exceptional strength and durability, making them a popular choice for various construction projects. The process begins with selecting high-quality hardwood logs, typically from sustainable forests, ensuring environmental stewardship. These logs are then carefully debarked, graded, and sorted based on specific criteria, including species, diameter, and quality.

The heart of the process involves a precise gluing technique. Strips of wood from these logs are cut to specified dimensions and glued together in layers, following engineering principles in glue laminated construction. This multi-layered approach, often referred to as laminating, enhances the beam’s strength and stiffness. After gluing, the panels undergo high-pressure treatment and careful drying to ensure they meet regulatory standards for glue laminated construction materials. Once cured, these beams are cut into the desired shapes and sizes, ready for assembly in structures like bridges, buildings, and wooden frameworks. For a comprehensive guide to gluing structural components, give us a call at (607) 369-9341.

Factors Influencing Custom Beam Cost Estimates

The cost of custom glue laminated beams is influenced by several key factors that go into their production and final properties. Understanding how glue laminated beams are made is crucial for accurately estimating costs. This construction method involves gluing together multiple layers of wood, creating a strong and durable beam. The choice of wood species, the number of layers (or laminations), and the type of adhesive used significantly impact both the structural integrity and the financial outlay of these custom beams.

Additionally, factors like the size and complexity of the beam design, required finishing touches such as machining or detailing, and any special performance characteristics (like fire resistance or enhanced load-bearing capacity) drive costs higher. Incorporating green building strategies that rely on glued wood and highlighting the sustainability benefits of glue laminated construction can also affect pricing, as these methods are becoming increasingly preferred for their environmental friendliness. Ensure compliance with relevant regulatory standards for glue laminated construction materials, which may add to overall expenses but are essential for safety and quality control. For detailed cost estimates, visit us at unalam.com anytime.

Calculating and Comparing Material Expenses

When calculating and comparing cost estimates for custom glue laminated beams, understanding the material expenses is paramount. The process begins with selecting high-quality timber, which significantly impacts the overall cost. Each type of wood has its unique properties affecting strength and durability. Engineers consider these factors to determine the best fit for structural requirements. Once the suitable timber is chosen, the focus shifts to the adhesive. Advances in wood adhesive bonding technology have enhanced the mechanical properties of different glues used for beams, ensuring both strength and fire safety features.

The choice of glue contributes to the overall cost; specialized adhesives designed for heavy-duty applications or specific environmental conditions carry premium prices. Additionally, labor costs play a significant role in the final estimate. Skilled technicians are essential for precise application and assembly, ensuring the beams meet industry standards and regulations, such as those outlined by organizations like UCLA (find us at unalam.com). Proper installation methods and adherence to safety protocols can prevent costly rework and ensure the longevity of the structural elements.

Understanding how glue laminated beams are made and the various factors affecting their cost is essential for accurate custom beam pricing. By considering material expenses, labor rates, and unique design requirements, you can gain a clear picture of what to expect when investing in these high-quality construction elements. Armed with this knowledge, navigating the process becomes more manageable, ensuring you secure the best value for your project’s structural needs.