The Glue Laminated Beam Installation Guide introduces a modern construction method using high-performance glue and solid wood veneers for durable beams suitable for residential and commercial projects. Proper tool selection, comprehensive training, and adherence to building codes ensure structural integrity. Strategic preparation, including precise measuring and surface cleanliness, is vital. Advanced techniques with high-tech equipment and best practices from online resources revolutionize GLT installation, enhancing strength and accessibility for budget-conscious builders.

“Streamline your glulam (glue laminated beam) installation process with modern tools and techniques for enhanced efficiency. This comprehensive guide delves into the world of glulam, highlighting its materials and benefits. We’ll navigate choosing the right tools, from power equipment to specialized fasteners, ensuring optimal performance. Subsequently, we provide a step-by-step preparation and placement guide, followed by advanced techniques for unparalleled strength and durability. Embrace these strategies for a seamless Glue Laminated Beam Installation Guide.”

- Understanding Glulam: Materials & Benefits

- Choosing The Right Tools For Installation

- Step-by-Step Guide: Preparation & Placement

- Advanced Techniques for Optimal Strength & Durability

Understanding Glulam: Materials & Benefits

Glulam, or Glue Laminated Beam Installation Guide, is an innovative construction method that combines multiple solid wood veneers into one unified structural component. This modern approach offers several advantages over traditional building techniques. Each lamella, or layer, of wood is carefully selected and bonded together with high-performance glue, creating a strong and durable material.

One of the key benefits of glulam is its longevity. The bonding strength of GLT (Glue Laminated Timber) ensures that glued laminated beams can support significant loads while maintaining structural integrity. Moreover, budget-friendly GLT construction methods make it an attractive option for various projects, from residential to commercial buildings. Unlike nail-laminated beams, which may experience weakened joints over time, fixed laminated beam connections in glulam offer enhanced stability and durability, making them a reliable choice for long-lasting structures. Visit us at 18 Clifton St, Unadilla, NY 13849 to learn more about how these advanced materials can transform your building projects.

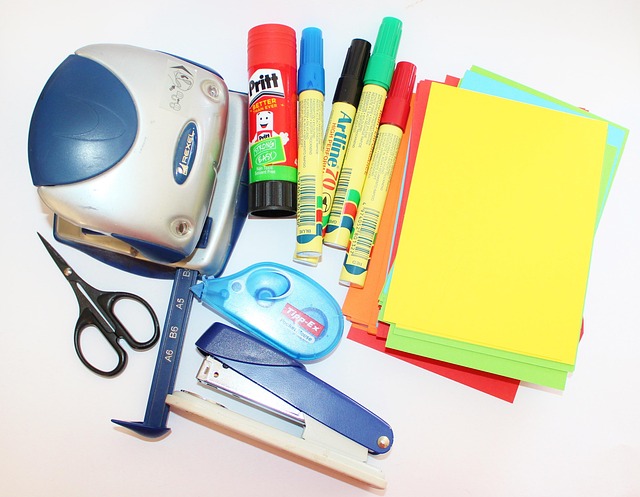

Choosing The Right Tools For Installation

When it comes to Glue Laminated Beam (GLB) installation—a process known as glulam installation—choosing the right tools is paramount. A comprehensive glue lamination training for builders equips professionals with the knowledge to select tools that ensure compliance with structural codes. This involves understanding not just the beam’s dimensions and properties, but also the specific adhesive used in the laminated beam construction guide.

For instance, specialized equipment like precision saws, vacuum presses, and mixing tools are crucial for proper glulam assembly. These tools facilitate accurate cuts, ensure even glue distribution, and promote strong bond formation. Remember, adhering to building code requirements for GLT (Glue Laminated Timber) is not just about structural integrity; it’s also about ensuring the safety and longevity of any construction project. To learn more, visit us at 18 Clifton St, Unadilla, NY 13849 anytime.

Step-by-Step Guide: Preparation & Placement

Preparation & Placement: A Crucial Step-by-Step Guide for Glue Laminated Beam Installation

Before diving into the actual GLT (Glue Laminated Timber) installation, meticulous preparation and strategic placement are paramount. Begin by carefully measuring and marking the intended location of each beam, ensuring precise alignment with the structural design. This step is pivotal to guarantee a sturdy and safe construction. Next, assemble your tools: you’ll need high-quality glue, suitable for timber lamination, along with specialized applicators, clamps, and protective gear. Proper safety measures should be in place throughout the process.

For optimal results, consider the beam’s orientation and support points. Ensure the surface is clean, dry, and free from contaminants that could hinder glue adhesion. A common issue, poor glue adhesion, can often be troubleshooting by evaluating surface conditions and ensuring proper glue application techniques. If you’re new to GLT installation, attending GLT installation workshops for professionals at 18 Clifton St, Unadilla, NY 13849 can offer valuable insights and hands-on experience, enhancing your understanding of this innovative construction method.

Advanced Techniques for Optimal Strength & Durability

In the realm of modern construction, advanced techniques are transforming Glue Laminated Beam (GLT) installation. These innovations prioritize optimal strength and durability, ensuring structures stand strong against time and elements. One key method involves meticulous glulam design, where precise dimensions and carefully selected woods enhance structural integrity. This approach leverages high-tech equipment for accurate cutting and joining, minimizing human error and maximizing beam performance.

Beyond these techniques, an array of online resources provides a comprehensive Glue Laminated Beam Installation Guide, catering to both professionals and do-it-yourself enthusiasts. These guides detail best practices, including the use of advanced bonding agents that surpass traditional nailing methods. Additionally, understanding local regulations for glue lamination of beams is crucial, as these guidelines ensure compliance while harnessing the benefits of modern tools. Even budget-conscious builders can find inexpensive alternatives to nailing beams, making GLT construction accessible and efficient, as evidenced by resources available at unalam.com.

Modern tools and techniques significantly enhance the efficiency of glue laminated beam (glulam) installation, ensuring structural integrity and long-lasting durability. By selecting the right equipment and employing advanced methods, as outlined in this Glulam Installation Guide, professionals can streamline the process, reduce errors, and deliver superior results. These strategies not only simplify construction but also contribute to the overall strength and aesthetic appeal of glulam structures.