Laminated wood beams offer a strong, sustainable, and cost-effective construction solution with customizable dimensions, exceptional strength, and fire resistance. Proper surface preparation and selection of high-quality connectors are key to maximizing their structural integrity and lifespan. Follow best practices for optimal performance and visit our location for top-quality products.

Laminated wood beams are a revolutionary material in construction, offering strength and versatility. This article explores best practices for connecting these innovative structural elements, ensuring robust and safe building. We’ll guide you through understanding laminated wood beam characteristics, preparing surfaces for seamless integration, selecting the right connectors, and verifying structural integrity during installation. By following these steps, builders can harness the full potential of laminated wood beams in modern construction projects.

- Understanding Laminated Wood Beams

- Preparing Surfaces for Connection

- Choosing Suitable Connectors

- Ensuring Structural Integrity During Installation

Understanding Laminated Wood Beams

Laminated Wood Beams for Construction offer an innovative and efficient solution for structural support in building projects. These beams are engineered by bonding together multiple layers of wood laminates, creating a strong and durable material that can withstand significant weight and span requirements. One of the key advantages is their customizable nature; architects and builders can tailor the dimensions, thickness, and design to suit specific project needs, ensuring optimal structural integrity while reducing material waste.

Not only do they provide exceptional strength, but laminated wood beams also contribute to eco-friendly construction practices. The use of timber as a primary component makes these beams a sustainable alternative to traditional steel or concrete structures. Furthermore, certain products are treated with fire-resistant properties, enhancing their safety value and offering peace of mind for both builders and occupants alike. For more information on how laminated wood beams can enhance your construction project, give us a call at (607) 369-9341.

Preparing Surfaces for Connection

Before connecting laminated wood beams, it’s crucial to prepare the surfaces for optimal joint strength and durability. Start by ensuring all beam ends are clean, free from debris, and any existing paint or coating is removed. Sanding the surfaces gently can help create a rough texture, allowing for better adhesion during the connection process. This preparation step is essential for build better with laminated timber structures, as it enhances the laminating strength to weight ratio, ensuring strong and reliable connections.

For old wooden beams requiring repair, this meticulous approach becomes even more critical. By carefully preparing the surfaces, you can effectively fix and reinforce these beams, extending their lifespan. Remember that a solid foundation is key; give us a call at (607) 369-9341 for expert advice tailored to your specific needs, ensuring your construction projects utilize the best practices for connecting laminated wood beams.

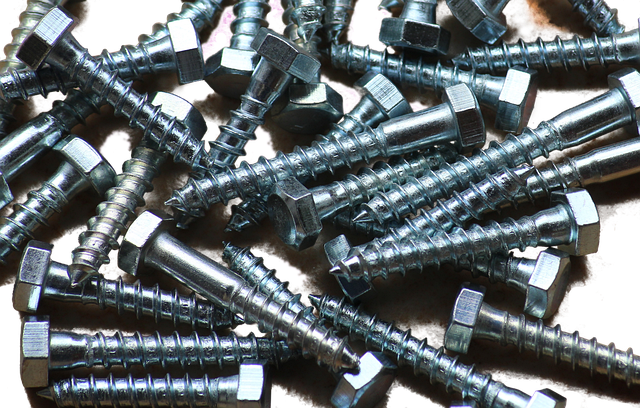

Choosing Suitable Connectors

When considering laminated wood beams for construction projects, selecting the right connectors is paramount to ensure structural integrity and longevity. Unlike traditional wood joints, which may be susceptible to warping or splitting, high-quality laminated wood connectors are designed to withstand elements like moisture and extreme temperatures, making them a superior choice for modern building practices. These connectors often feature innovative designs that enhance bond strength, providing both stability and flexibility during installation.

To ensure you choose the most suitable connectors for your specific needs, consider factors such as load capacity, material composition, and compatibility with your laminated wood beams. Additionally, consulting industry standards and guidelines can offer valuable insights into best practices. For personalized advice on how to select the right laminated wood beams and durable connectors, give us a call at (607) 369-9341.

Ensuring Structural Integrity During Installation

Maintaining structural integrity is paramount when installing laminated wood beams for construction. Proper connection methods are critical to ensure these innovative building materials withstand the elements and solve structural issues effectively. When done right, laminated beams offer a cost-effective solution that combines strength and sustainability. Eco-friendly laminated wood options are now available, featuring fire resistance as an added benefit. To guarantee optimal performance, follow best practices for connecting these beams, ensuring they seamlessly integrate into your construction project.

Whether you’re a professional contractor or a DIY enthusiast, paying close attention to the details of installation is crucial. Visit us at 18 Clifton St, Unadilla, NY 13849 anytime to explore our range of high-quality laminated wood products and gain expert insights on achieving structural excellence in your building endeavors.

When connecting laminated wood beams for construction, adhering to best practices ensures structural integrity and long-lasting joints. Understanding the unique properties of these beams, preparing surfaces meticulously, and selecting appropriate connectors are vital steps. By prioritizing these aspects during installation, builders can create robust connections that support the demands of modern construction projects. Incorporating these strategies into your workflow will ensure superior results when working with laminated wood beams.